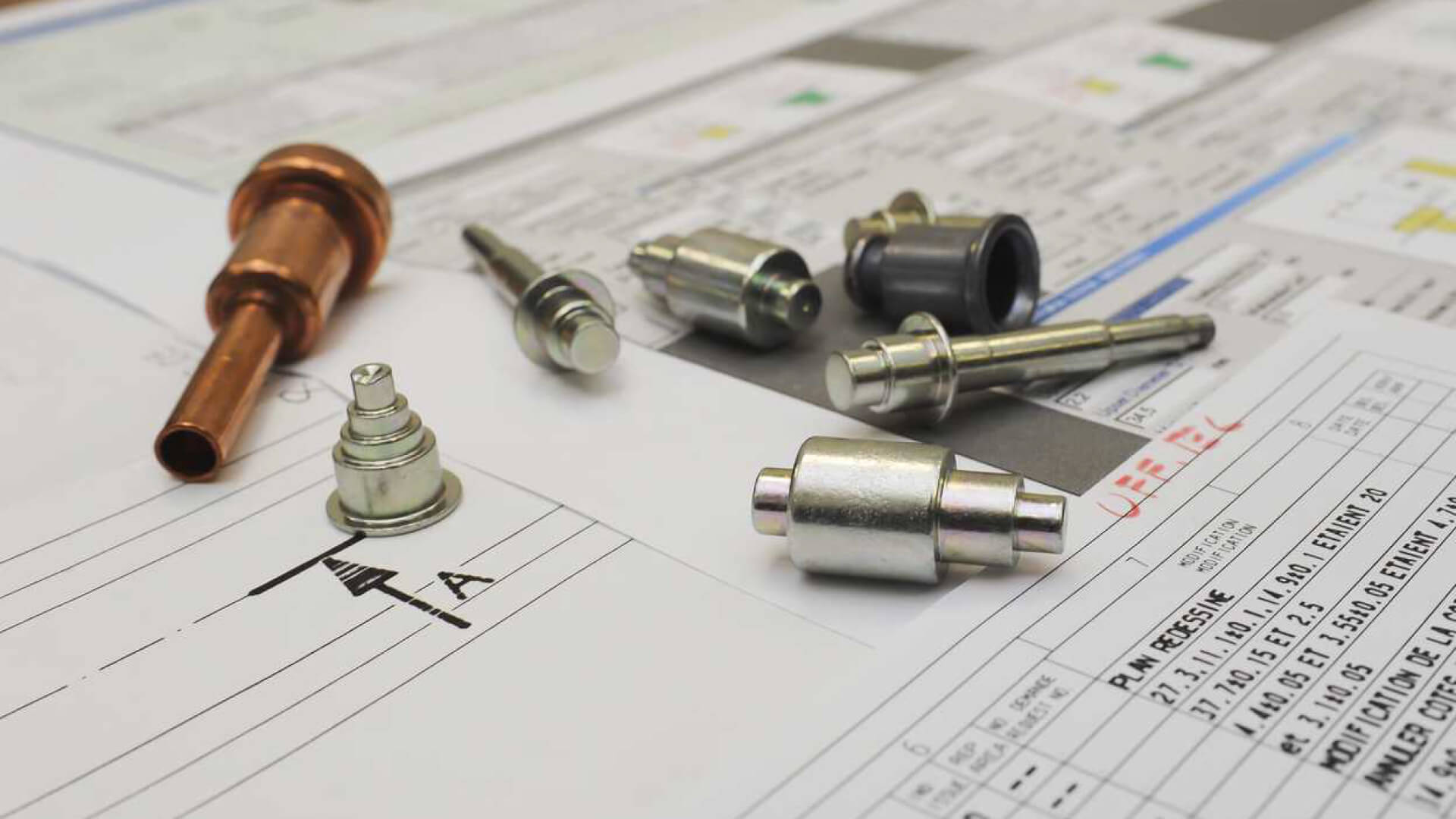

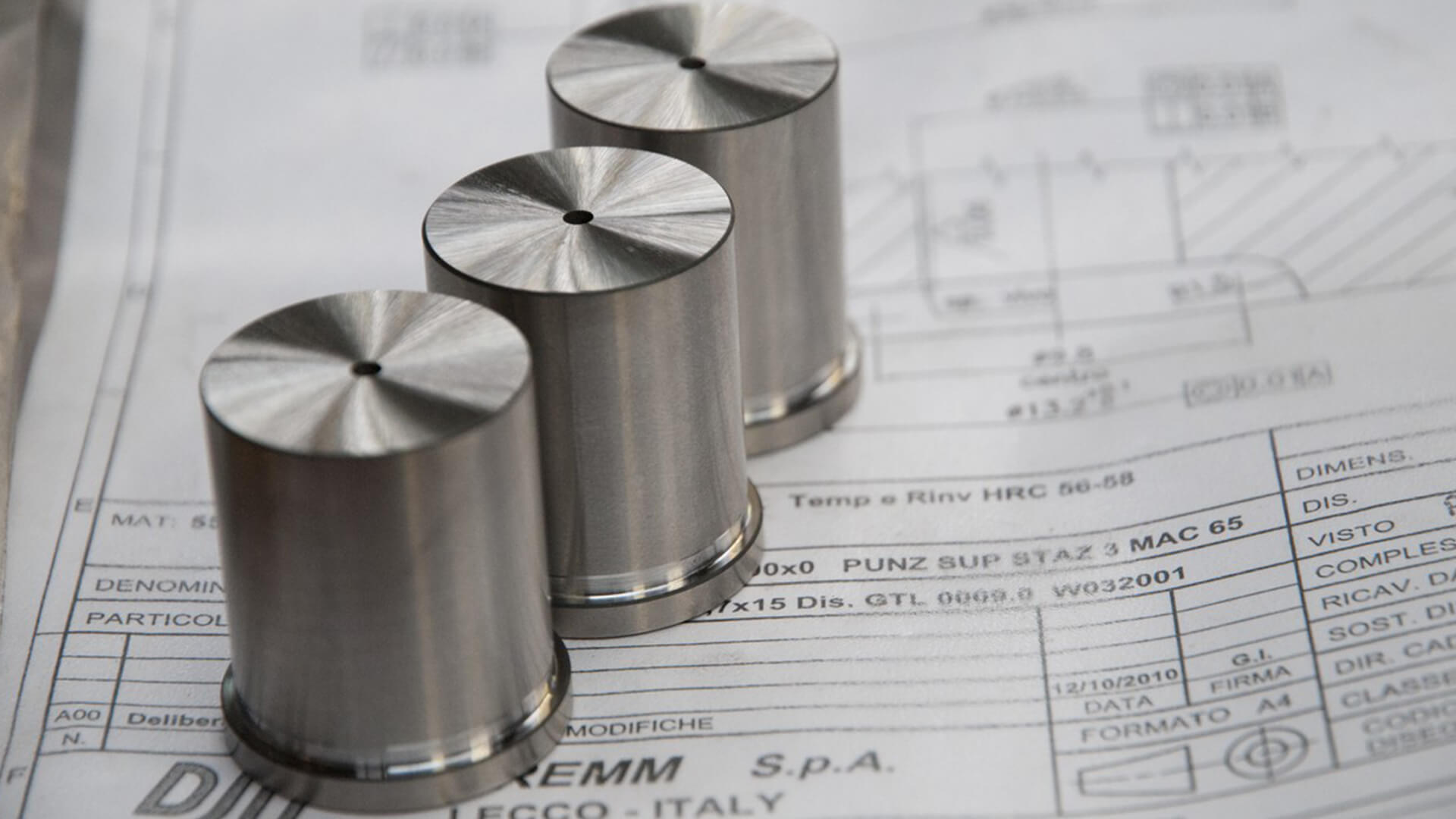

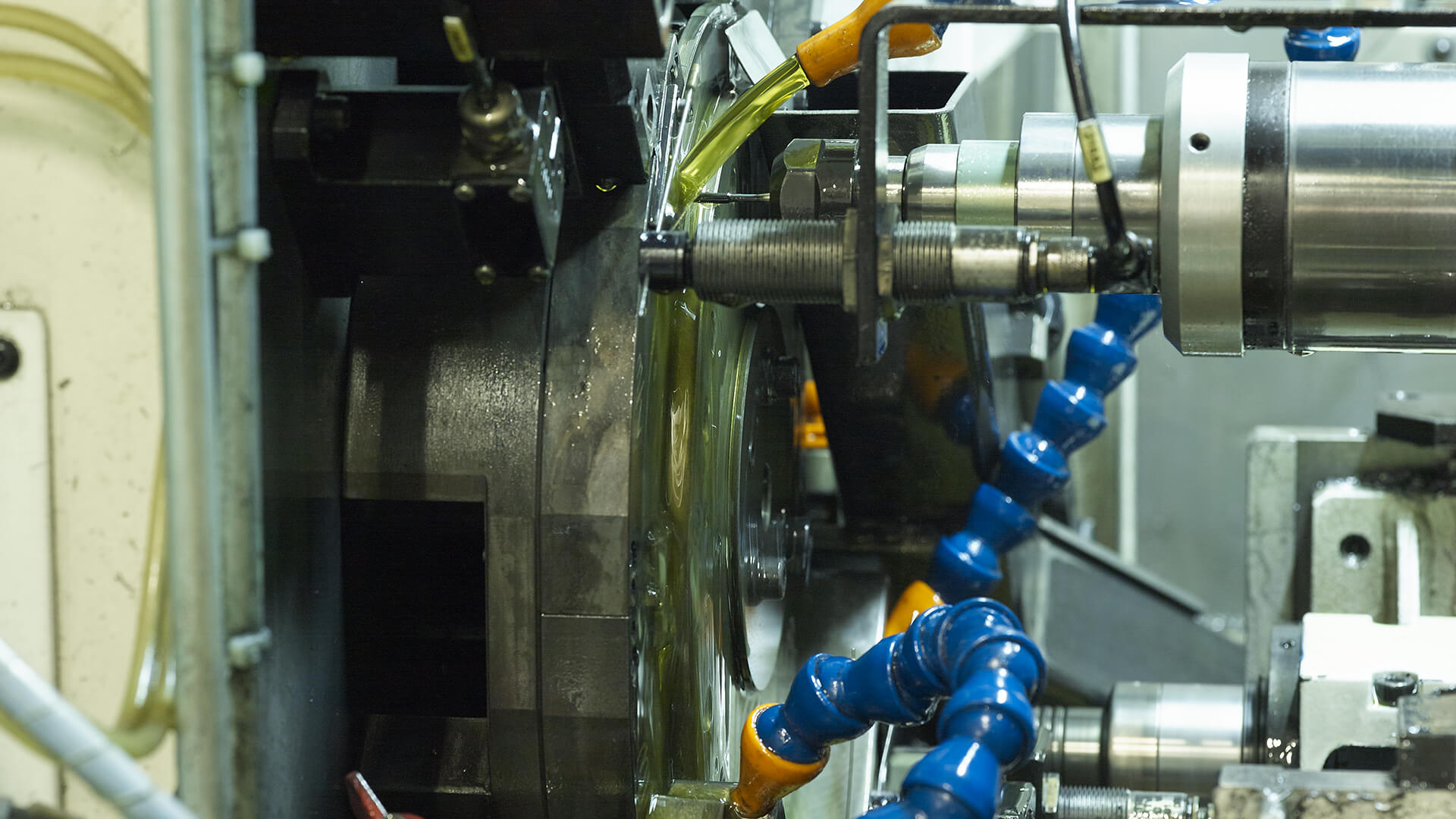

From prototyping to delivery of final products

DEFREMM Spa P.IVA 00814480133 | Social capital 780.000€ fully paid | Conditions of sale | Privacy & Cookie Policy | Designed by Webtek S.p.A.